Bare Fiber Polishing

Bare Fiber Polishing and Inspection

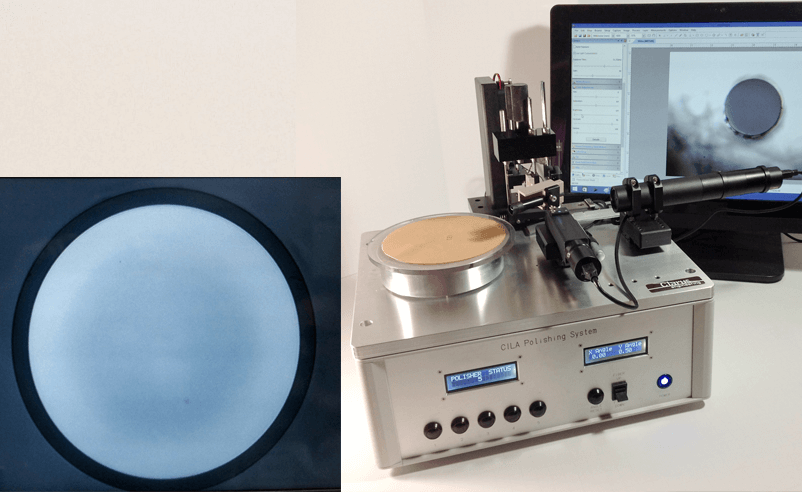

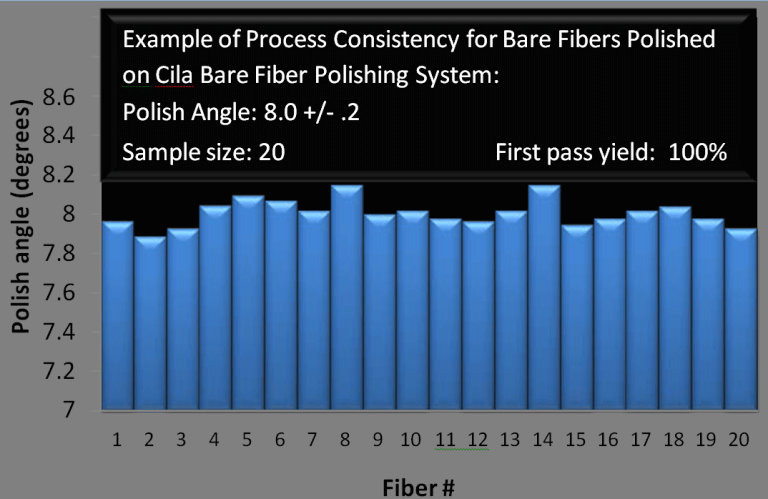

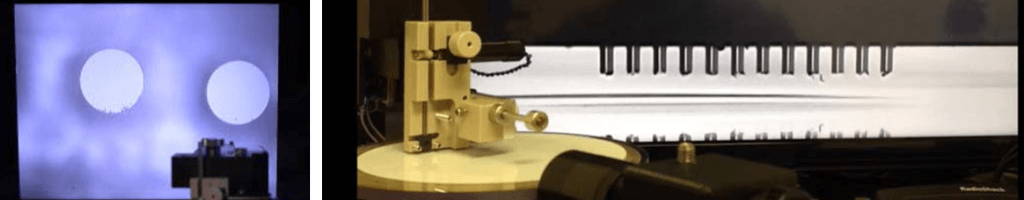

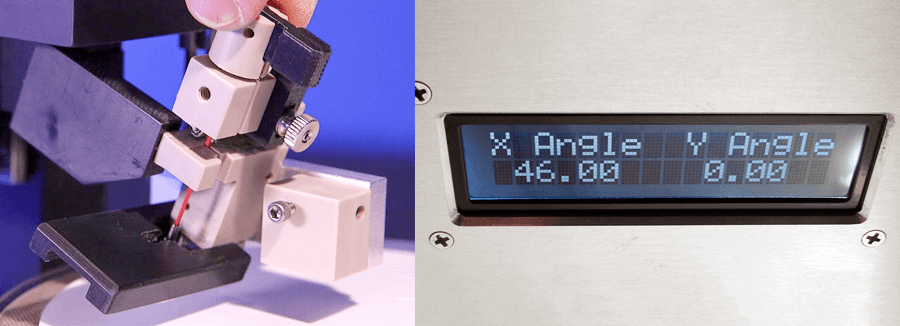

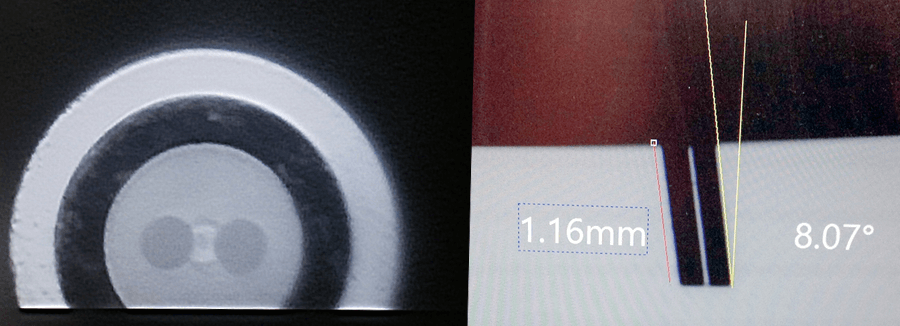

The Cila 2.0 Bare Fiber Polishing and Inspection System can efficiently grip, align, position, and polish bare fibers to a multitude of exotic geometries. Built-in inspection systems (profile and in-line brightfield) provide high-resolution imaging and referencing, making it an effective tool for applications when demanding tolerances for polish angles, radial alignment (PM fibers), and precise fiber protrusion lengths are required.

Features

- Configuration supports single position polishing of high-value fiber optic assemblies

- Profile view, high-resolution video inspection system for process monitoring and inspection. Angular accuracy: +/-.05 degrees, Linear accuracy: +/-5 um

- Precision angle adjustability from 0-82 degrees with digital readout

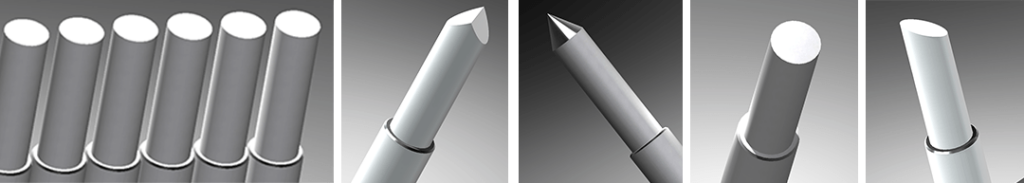

- Bare fiber polishing (single or ribbonized) without cleaving

- Polarization maintaining fiber alignment and polishing

- Faceted, chiseled, and other complex end-face polishing

- Metrology option for precise measurements for length, angle, and radial alignment